Sla quickcast supplier pro#

“We continue to invest in new facilities and equipment, such as our recent acquisition of two more SLA Pro X800 systems and an SLS sPro 60 machine. Our completely redesigned website creates a more user-friendly experience, provides more resources and information, and expedites the job submission process, allowing for faster delivery of prototyping and production orders. Plus, we have augmented our selective laser sintering (SLS) capacity with the addition of a new sPro 60 system. providers for rapid prototyping and production.Īs part of this expansion, we’ve augmented our Stereolithography (SLA) QuickCast post-processing and finishing, and CNC machining capacities. We’ve expanded our facility in Oxnard, California to over 15,000 square feet to offer key 3D printing technologies in-house, making us one of the few comprehensive U.S. Our Expanded Facility Means Customers Get Faster Service for SLS, SLA, FDM and CNC Projects

Any of the Technical Data files that I will submit for this project (or the product(s) to which the Technical Data relate) is subject to the Export Administration Regulations (EAR), 15 C.F.R.Any of the Technical Data files that I will submit for this project (or the product(s) to which the Technical Data relate) are controlled by the International Traffic in Arms Regulations (ITAR), 22 C.F.R.Answer “Yes” above if either of the following apply: If you have both ITAR/EAR orders, you will need to register on both instances.

We need this information to ensure that we treat your Technical Data in accordance with U.S. We require additional information about the production and design information (i.e., Technical Data) that you will provide in connection with your project, as well as the product to which the Technical Data relates. The cookie is set by the GDPR Cookie Consent plugin and is used to store whether or not user has consented to the use of cookies. The cookie is used to store the user consent for the cookies in the category "Performance". This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Other. The cookies is used to store the user consent for the cookies in the category "Necessary".

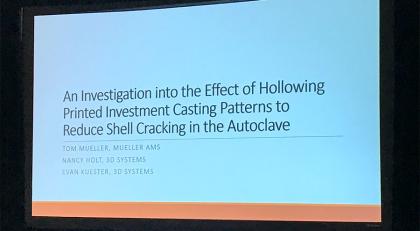

The cookie is set by GDPR cookie consent to record the user consent for the cookies in the category "Functional". The cookie is used to store the user consent for the cookies in the category "Analytics". These cookies ensure basic functionalities and security features of the website, anonymously. Necessary cookies are absolutely essential for the website to function properly. However, most commonly, we choose between SLS, SLA, and FDM patterns for the casting manufacturing process. Your team will have easy access to molds needed for low-volume production. We infiltrate them with wax to facilitate easy removal and create complicated patterns.īased on your production needs, Quickparts provides the best investment casting patterns. The overall density of these patterns is low. We also print SLS casting patterns using the CastForm process. In addition, the hollow pattern has a reduced volume for faster drainage of the pattern during the casting process. This approach involves a hollow stereolithography pattern with a proper structure to make the design stronger. Our professionals use the QuickCast build style for SLA casting patterns. Our professionals also pay attention to the surface finish. To avoid defects, we produce patterns to close tolerances. To accelerate the FDM pattern burnout, we add venting to ceramic shells. We then remove it while cleaning the shell cavity. They do not melt like wax but leave some ash in the cavity. We use Fused Deposition Modeling patterns to replace injection-molded traditional parts. We specialize in different additive manufacturing methods

0 kommentar(er)

0 kommentar(er)